HIGH-QUALITY PRODUCTION WITH OUR TECHNICAL COMPETENCIES

TKG Otomotiv is a company that designs and manufactures presses, welding parts and heat shields for its customers in the automotive industry and offers innovative solutions with the aim of becoming a ‘co-designer’ in alternative products and product groups. Integrating the latest technologies into its production processes through its innovative perspective since the day it was founded, TKG Otomotiv has been manufacturing heat, thermoacoustic and electromagnetic shield product groups for global companies and producing innovative parts that can respond to the changing needs and demands in the automotive industry with automated systems and technological investments such as transfer press and roll form line.

TKG Automotive, which understands the expectations of its customers and offers them the most accurate products and solutions with the strength it draws from more than 45 years of experience, is a global company that gives confidence to its stakeholders, always uses the state-of-the-art engineering technologies by making investments in parallel with the developing technology, and manufactures products in accordance with IATF 16949 Quality Management System, ISO 14001 Environmental Management System and ISO 45001 OHS Management Systems in 6 different plants with a total closed area of 65.000m².

PRESS STAMPING

With our press forming technologies, we shape steel and aluminium sheet metal parts, thus reducing the weight of vehicles while manufacturing high-strength parts.

We utilize the following technologies while performing press forming:

Transfer Press Line

Progressive Press Line

Robotic Press Line – G2

Tandem Press Line

Embossing Line

The Parts We Produce Through Cold Stamping Technology:

Skin Panels

BIW Components

Heat / Acoustic / Magnetic Shields

Powertrain Components

Seat Frame Components

Chassis ve Suspension Components

INSTALLATION

As TKG Automotive, we assemble the products on part-specific assembly lines, within the instructions prepared by our experienced assembly team and technical team. we are. We prevent possible operational errors with the Poka-Yoke system. Our assembly technologies;

PVC installation,

Rivet installation,

Adhesion technologies (Tape, sponge, mastication)

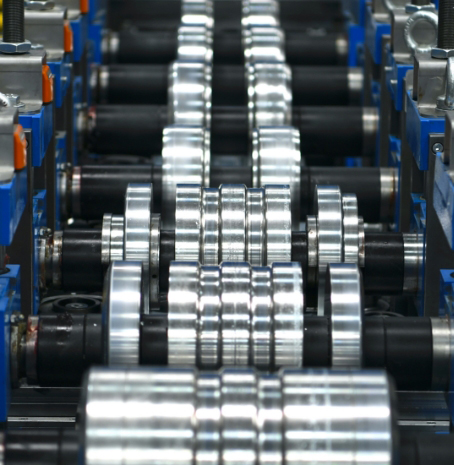

ROLL FORMING

We achieve maximum efficiency with minimum material use by producing bumpers within the scope of collision systems through our roll forming line, which has an integrated laser welding process and produces parts with full automation from raw material to the final product.

Products we produce with roll forming technology:

Bumper Crash Beams

Side Door Beams

Electric Vehicle Battery module covers

WELDING

We use state-of-the-art welding lines for the assembly of high-strength steel and aluminium parts. Thanks to our advanced welding technologies, we minimize deformation during welding. Our welding technologies are listed below:

Laser Welding

Gas Metal Welding Robots,

Projection Welding,

Spot Welding,